http://visual.merriam-webster.com/energy/geothermal-fossil-energy/oil/drilling-rig.php

For

the

power

system (picture left), it basically provides

all the necessary power to carry out the drilling work. Normally this

power is generated from local combustion generators. A common drilling

rig requires

approximately 1000-3000 horse power to maintain the operation. However,

the

power efficiency can be varied from place to place. Generally, the

mechanical efficiency

of the generator is favorable to work in low altitude and medium

temperature

environment.

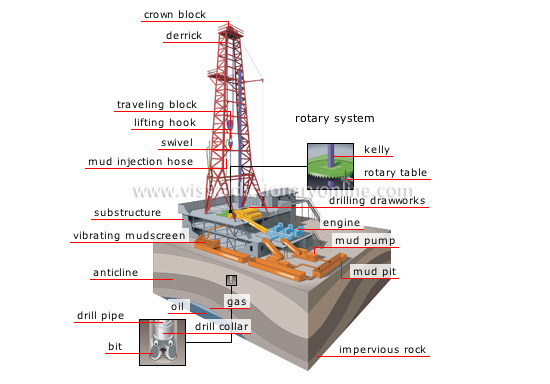

Hoisting system (picture right) is one of the main parts to actually doing the drilling job. Either drill pipe or casing will be lifted and lowered to drill and complete the well. It mainly composes of the derrick, tackle &block system and dead line anchor system. Tackles and block do the vertical movement to the pipe. People working on the derrick can help to safely place these pipes to the right position. The dead line anchor mainly helps the replacement of the drilling line when it was subjected to wearings.

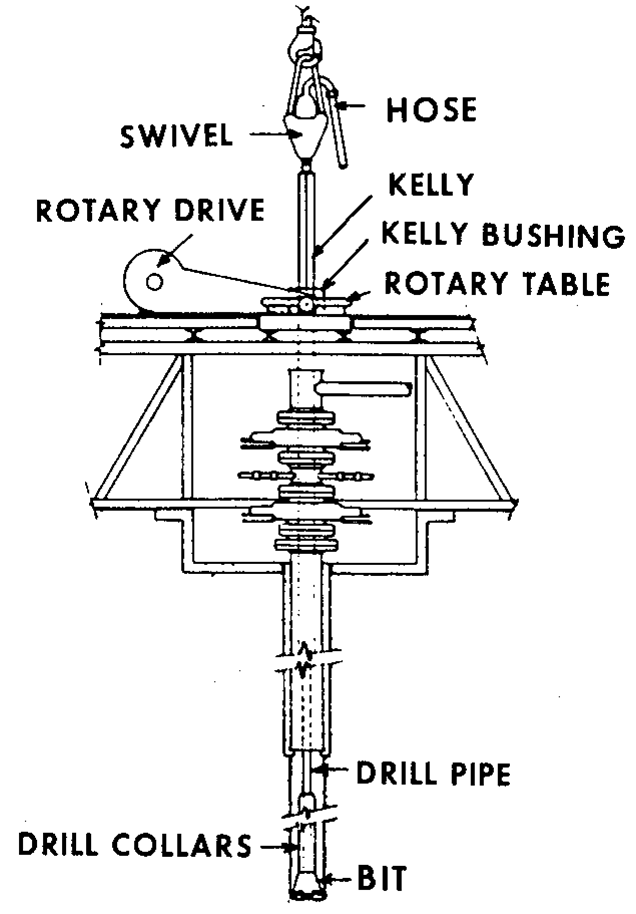

Wells are drilled by the pipe &bit rotation, therefore it is very important to have an efficient rotation system (picture left). This system mainly includes swivel, Kelly, rotary drive and rotary table. The working principle of rotation system is the Kelly, which is connected to the drill pipe drove by the rotary table and then the whole drilling string can be rotated for drilling.

In order to keep the drilling operation without big troubles, proper circulation system (picture right) should be built to fulfill the requirement. Working scenario of circulating system is the drilling mud will be pumped into the drill pipe from the mud reservoir, we called it mud pit. After mud reached the bottom the well, it brings rock cuttings to the surface through the annulus between drill pipe and well wall. The mud with rock cuttings will be separated through surface solid control system, such as screens, desanders or centrifuges. After these, clean drilling mud will be retreated with certain chemicals and again pumped into the wellbore.

Drill a well is very dangerous, because the pressure in the reservoir could be significant high, which normally about couple thousands psi. Therefore, in order to guarantee the drilling operation safe and prevent undesirable accident, well control system must be installed. The main part of this system is the blowout preventer (BOP, see picture left). This equipment is set on the top of the well bore. If there is a sudden pressure change in the well which push the formation fluid up to the surface, BOP will be closed the seal the well from blowout.

The working platform for drilling work is called drilling rig. It holds the most components required for the drilling work. Main components comprise the drilling rig are:

1. Power system

2. Hoisting system

3. Rotary system

4. Circulating system

5. Well control &monitoring system